Once a project is awarded to The Arthur Louis Steel Company the fabrication process begins with the assignment of each project to our Detailing/Engineering Department. Our detailers use one of the following programs to generate the detailed fabrication and erection drawings for our projects:

- RAM structural

- SDS/2

- TEKLA

- AUTOCAD

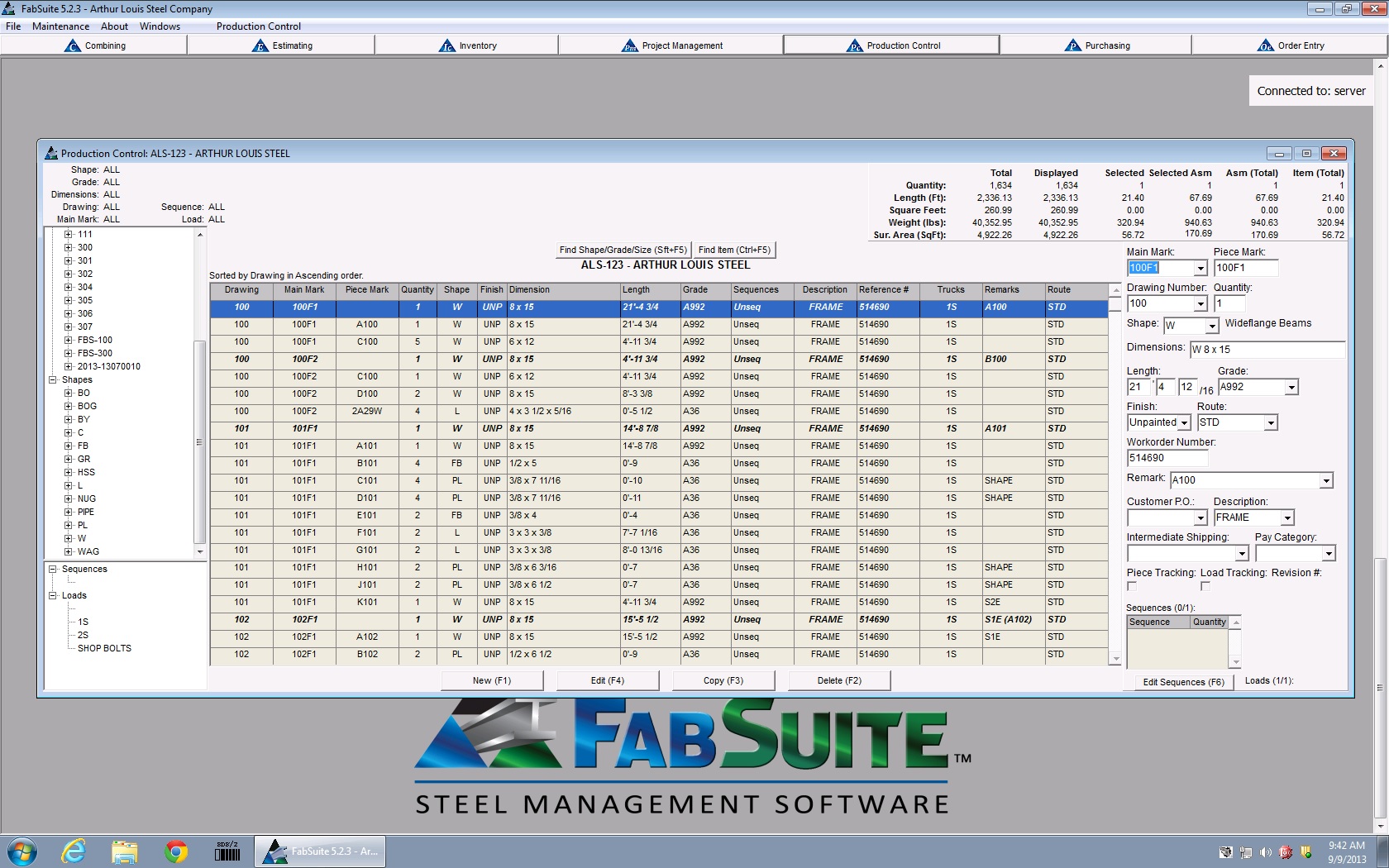

- Submit drawings for customer approval

- Multing and nesting materials for procurement purposes

- Generate work orders for distribution to the shop floor to begin production

- Generate and manage all purchase orders related to each project

- Manage and document all drawing revisions

- Manage and document any project related change orders

- View real-time production status (along with overall project completion benchmarks)

- Complete project management activities such as scheduling

- Record all QA/QC transactions for main and accessory steel members

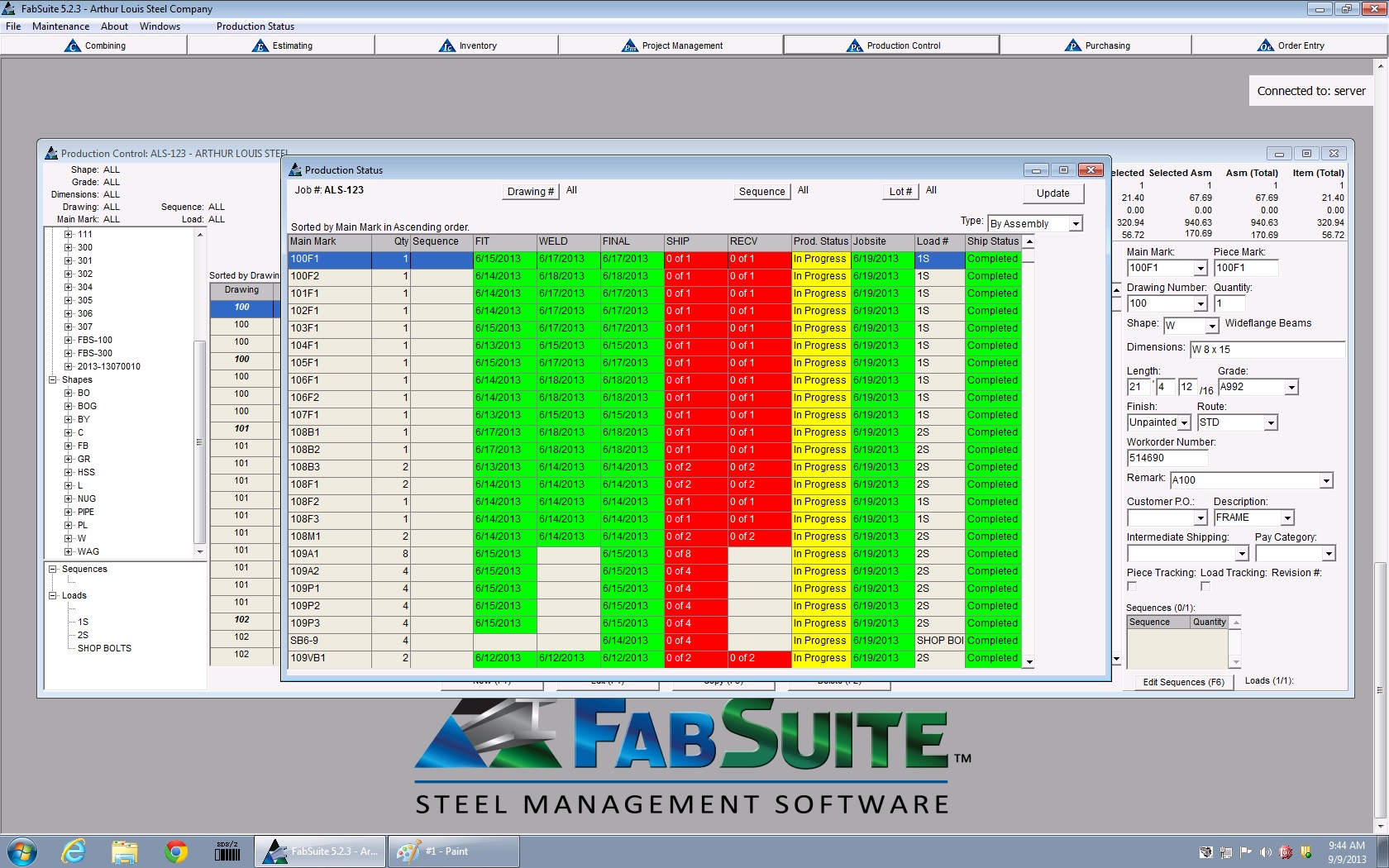

- Receive/Reject inbound raw materials

- Approve/Reject initial fit of main member assemblies

- Approve/Reject weld process

- Approve/Reject final QA inspection

- Load trucks to coating contractors

- Receive material back from coating processes

- Create bundle lists for small parts being shipped on skids

- Load trucks to jobsite

- Controlled Automation CNC DRL-336 Three (3) Spindle Drill Line with 44" Capacity HEM Saw in Tandem (drill up to 1.3125” round hole in W36 wide flange beams)

- Controlled Automation 2AT-175 CNC plate duplicator with 175 ton punch capacity (punch up to 2.75” round holes in 1.5” thick hot rolled plate)

- Accurpress 400 ton CNC Controlled Hydraulic Press Brake (form .375” thick plate x 12’ long)

- Controlled Automation ABL86 CNC Angle and Flat Bar Line (punch up to 1.315” round hole in 6 x 6 x .625” thick hot rolled angle or flat bar)

- C.A. CNC Dual Gantry Plasma Table 12’x 80’ capacity with Hypertherm 260XD and 400XD power supplies (production cut up to 2” thick plate on dual gantry 12’ x 80’ long water table)

Utilizing state of the art technology and automation allows The Arthur Louis Steel Company to reduce cycle time and compress project schedules. Work order generation, drawing control and production floor CNC equipment programming that previously took several days to complete when performed manually can now be completed in a matter of hours while eliminating errors associated with manual data entry. The Arthur Louis Steel Company is extremely proactive when investigating and implementing new software and investing in new equipment. Our philosophy is to embrace the latest available technology in order for us to improve quality, project cycle times as well as to reduce internal costs. This philosophy has permitted us to improve our competitiveness in the global marketplace and become the supplier of choice for our customers.

|

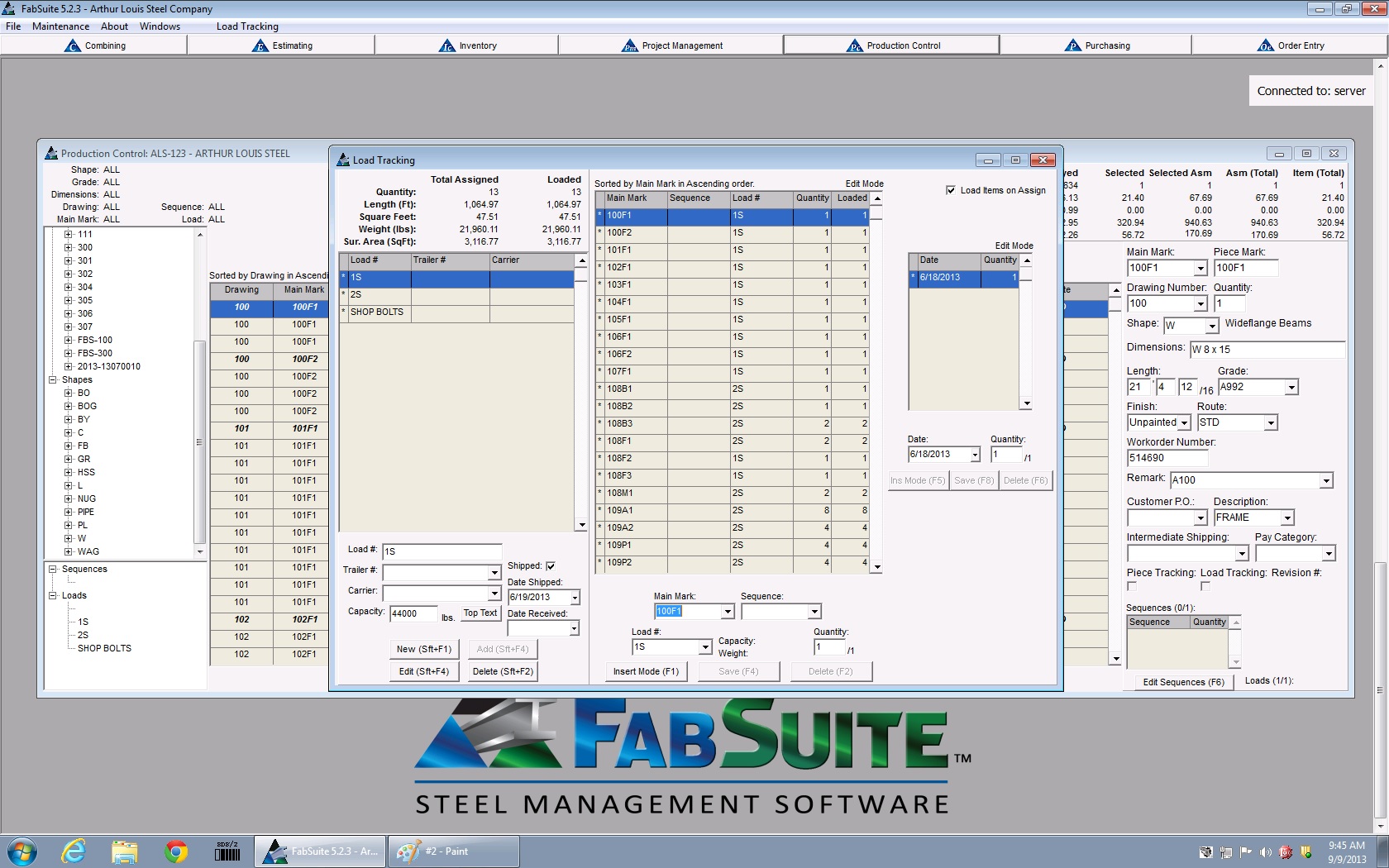

FabSuite Steel Project Management Software Screenshot |

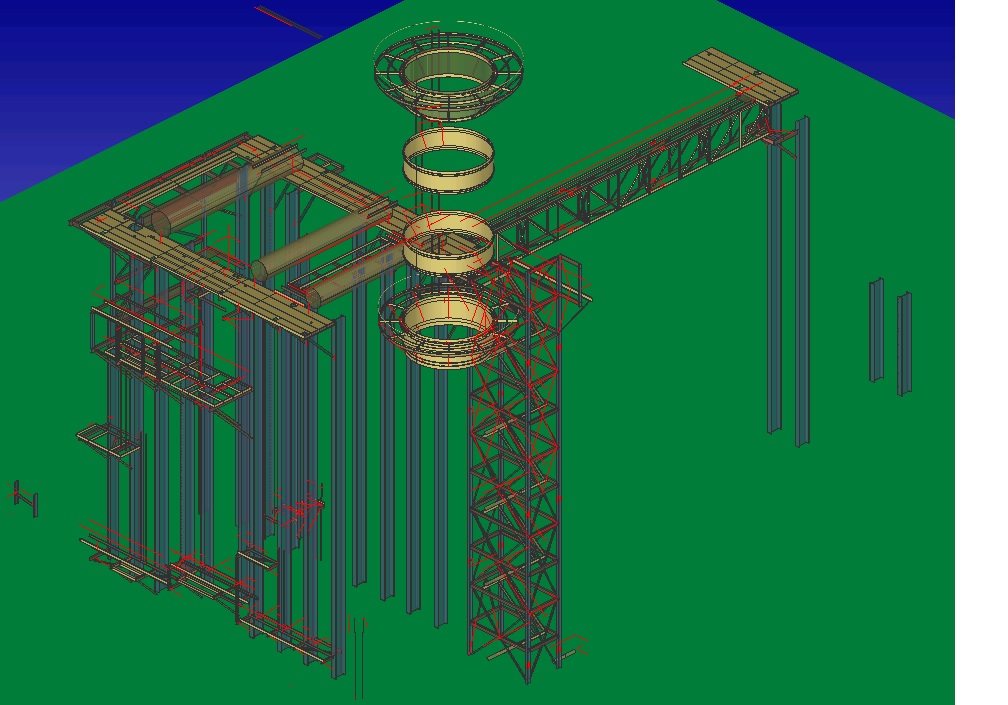

RAM Engineering/Design Software Model Screenshot |

|

P2 Programs Bar Code Tag |

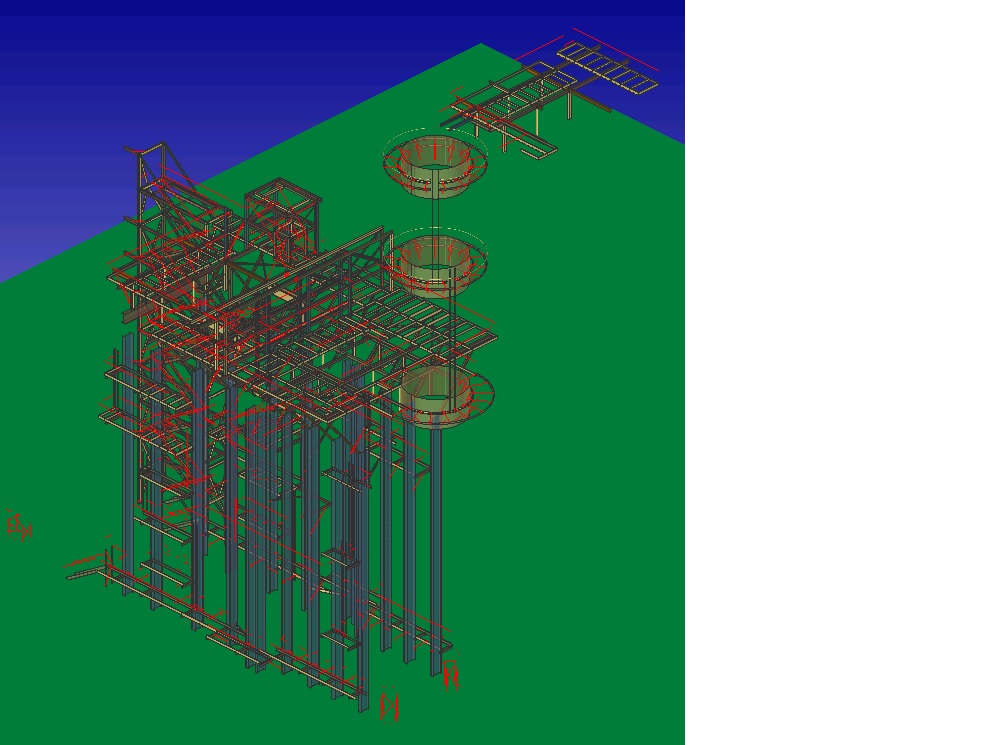

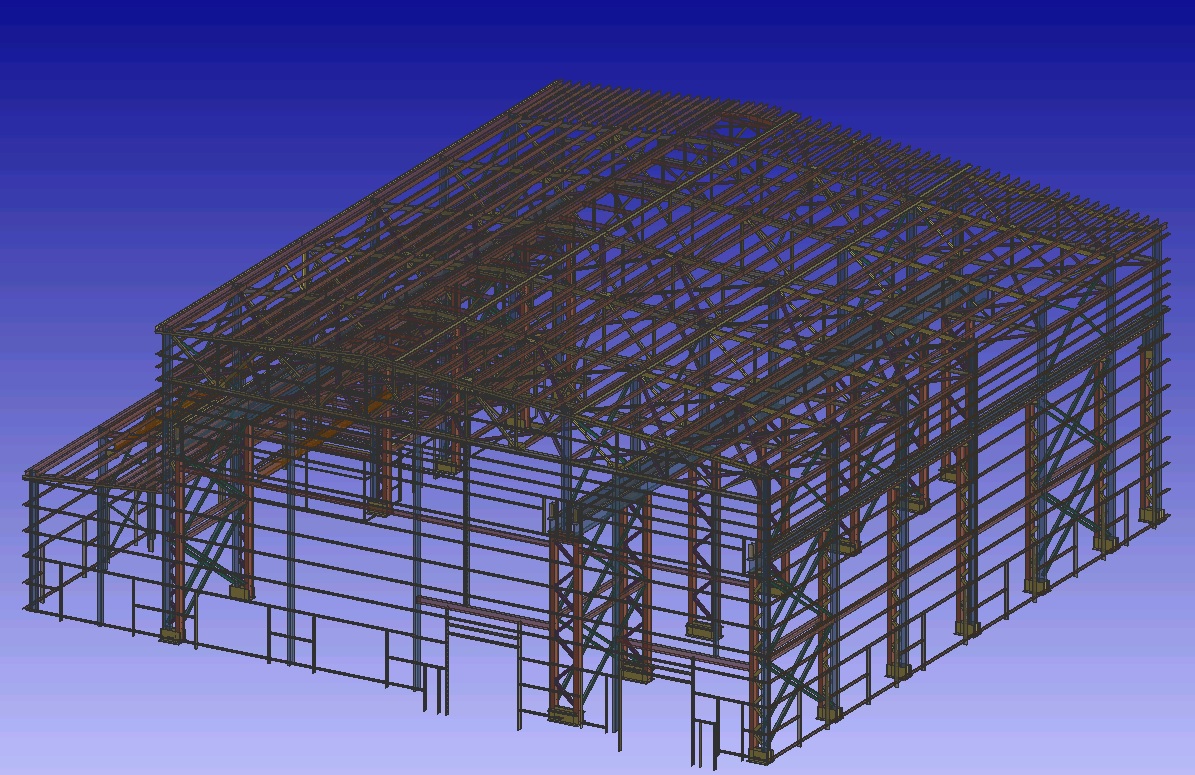

SDS Steel Detailing Software Model Screenshot |

|

2AT-175 PLATE PUNCH |

MULTIMAX PLASMA TABLE |

|

ABL-86T ANGLE LINE |

DRL-336 3 SPINDLE DRILL LINE |

The Arthur Louis Steel CompanyWhen Quality & Delivery Count

All content © Arthur Louis Steel Company 2024